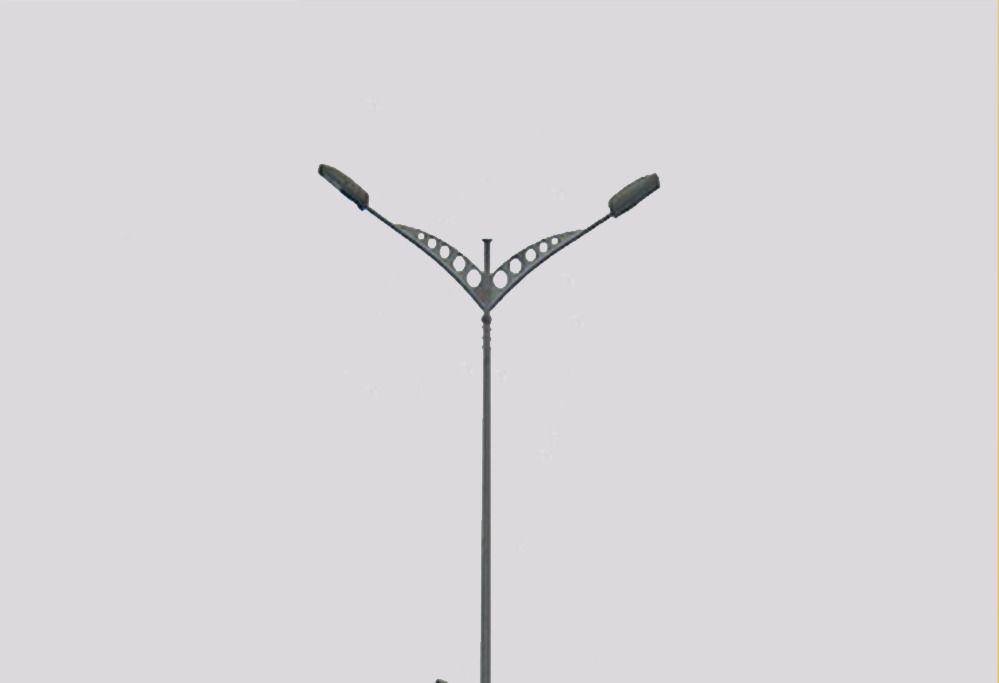

Lighting tower is widely used for lighting large areas such as parks, promenades, squares, streets, bridges, buildings such as hospitals, factories, etc. Lighting towers or lighting masts are the opposite of street lighting bases in terms of application, because lighting towers or light towers are not suitable for lighting places that are long and narrow.

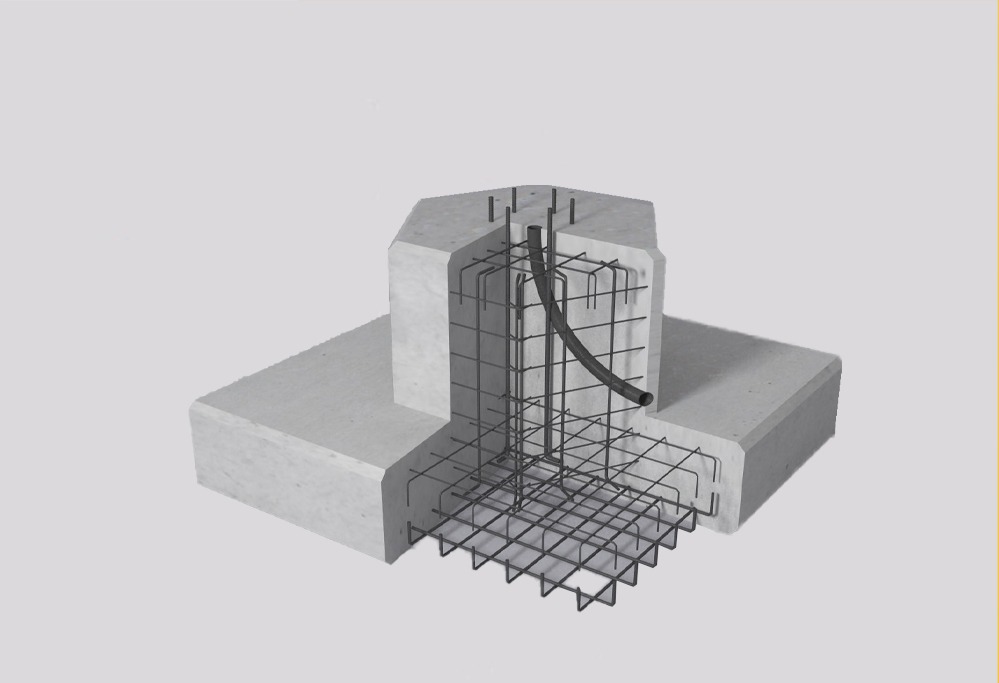

In the design and construction of lighting towers, the following items should be considered:

- wind speed and wind pressure forces in the region;

- Earth structure and soil type;

- The weight of the tower to calculate the foundation;

- resistance to earthquakes and other natural disasters;

- compliance with international standards;

Lighting tower

Ehdas Gostar Nirooye Pars Engineering Company has received CE1282 and ECM international certificates and has adapted its products to European standards.

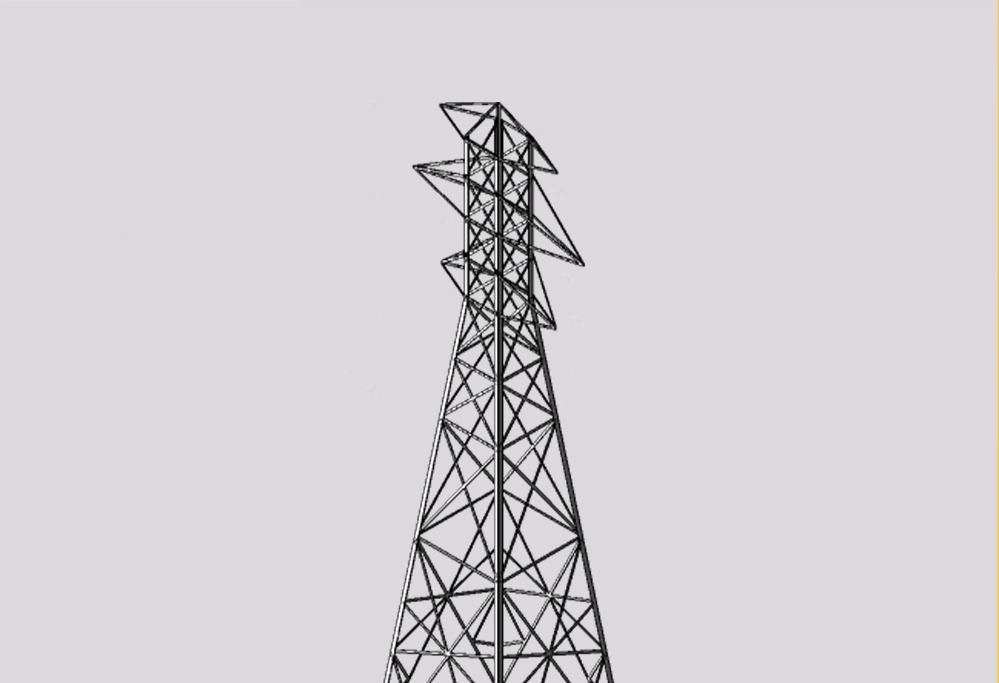

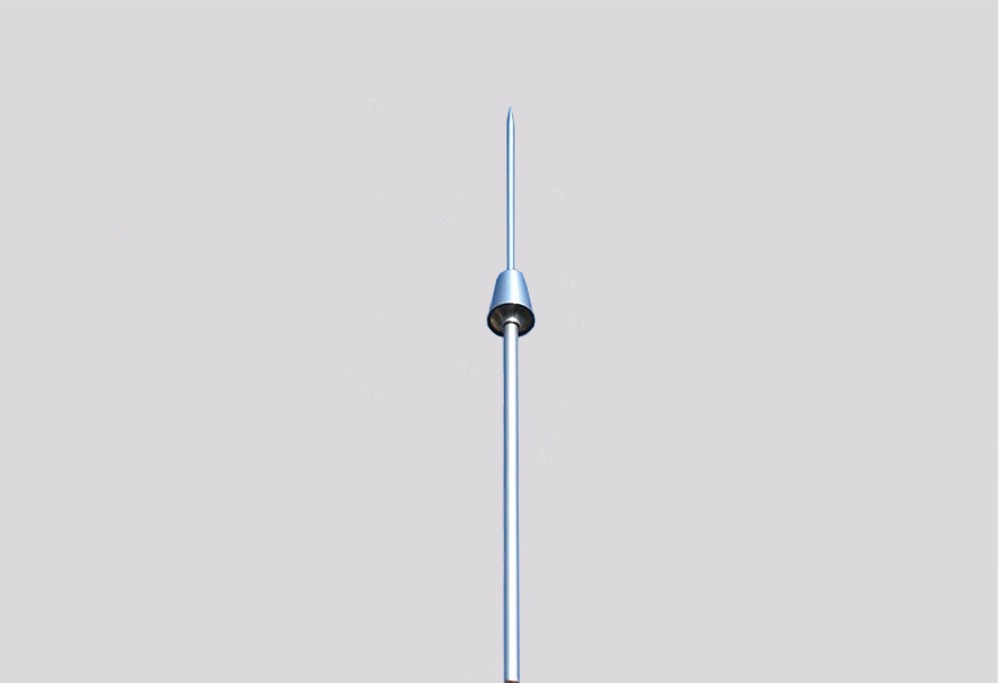

Lighting towers are manufactured in three designs of fixed basket light tower, mobile basket light tower with manual handle and mobile basket light tower with electric motor at common heights ranging from 12 to 60 m. Their external surface is protected by hot-dip galvanized coating, and their parts are joined together using an overlapping assembly method, and the safety of their basket is ensured by interlock and parachute locks.

What is a lighting tower?

This section describes lighting towers? Lighting towers are high-height metal structures that have a number of floodlights with different powers. They are used to illuminate large areas. Lighting towers are polygonal. Zinc coating is used for coating the metal sheet. To manufacture a lighting tower, first, data such as the geographical location of the installation, the amount of wind in the region, the region seismicity, and the lighting tower height should be collected and then submitted to the design department. Lighting towers are usually determined in 6m sections with certain distances from the top and bottom openings of the sections. Note that the number of tower sections and the exact dimensions of each tower should be determined so that it can better bear the weight of the structures and resist shocks Refer to the price page of the polygonal tower for information.

Fail-safe basket locking system (parachute)

Fail-safe basket locking system was designed and produced by the engineers of Ehdas Gostar in 2011. In this system, if the tow wire breaks or a malfunction occurs when the basket is lowered or raised, the locking system prevents the basket from falling.

This system is important in the sense that it also prevents the wire rope fatigue besides reducing the pressure on the gearbox and prevents the basket from falling and causing life and financial damage in cases where the tow wires break.

Advantages of the parachute system in lighting towers

- Reducing life and financial risks

- Reducing specialists’ stress in charge of assembly and installation

- Fail-safe basket lowering system

All lighting towers produced by this company are equipped with this system. To safeguard the basket in case of a cable failure, an anti-fall basket locking system is employed. This system automatically engages if the towing wire breaks during basket raising or lowering.

Manufacturer of lighting towers

Manufacturers should take into account the wind speed and wind pressure in the region, soil type, tower weight, earthquake resistance, and international standards in the design and construction of lighting towers.

Ehdas Gostar Nirooye Pars Engineering Company has received CE1282 and ECM international certificates and has adapted its products to European standards.

Lighting and optic poles manufacturing engineers at Ehdas Gostar Nirooye Pars Engineering Company manufacture lighting towers ranging from 12 to 60 m in three designs: fixed basket, movable basket with manual handle, and movable basket with electric motor.

The external surface of the lighting tower is insulated by hot-dip galvanized coating and their sections are joined together using an overlapping assembly method, and the safety of the basket is ensured by interlock and parachute locks.

Lighting tower and maintenance

The whole lighting maintenance includes floodlight installing steps, electrical panel replacement, gearbox repair, replacing the light bulb, and lighting tower cleaning. These practices should be done in certain time to guarantee products’ integrity. To facilitate the maintenance process, floodlights’ head holder is located on top of the tower and is movable. The lighting towers have different sizes and are designed and manufactured based on the customer’s request and in the form of flanges. The type of coating chosen for lighting towers is different according to the weather conditions.