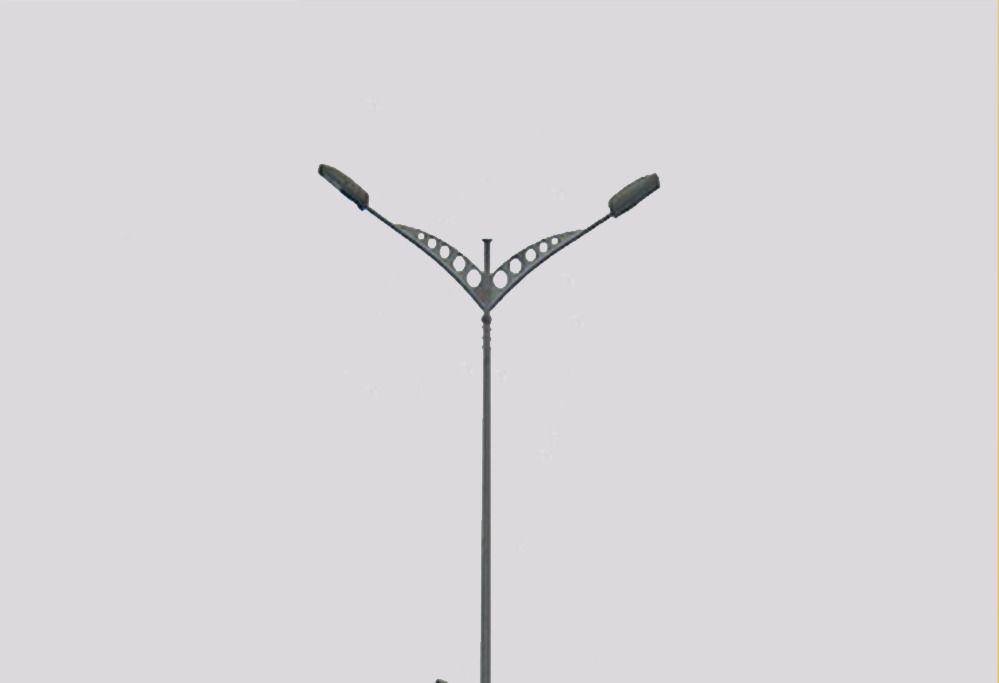

Street lighting pole There are a variety of street lighting poles, including polygonal and tubular lighting poles and are manufactured depending on customer demand and the design of urban roads and highways at 3 to 18m heights. They are offered in different designs for standard passage lighting with branches fitting the passage length, angle, and width, the pole distance from the refuge, and the type of light distribution. These poles can be supplied in different shapes and sizes with the required number of headers. The tube design and the distance between the poles are calculated by special software. The street lighting pole coating is determined according to the climate of the region and durability. The coating can be hot-dip galvanized, electrostatic paint, epoxy paint, etc.

Street lighting pole

The street and highway lighting poles can be the best option for lighting streets and highways Unlike some lighting poles, known as light towers and used to illuminate a large area of the place, this type of lighting pole is suitable for illuminating long narrow environments. Different types of street lighting poles are manufactured in polygonal and tubular forms using a single-seam construction, which can be installed on one- to four-floodlight street lighting pole. The type of tubes used in the manufacture of street lighting poles is adjusted according to their height. The higher the height, the stronger the type of tubes used in the construction of the street lighting pole. According to the type of order, street lighting poles can be made.

Street lighting pole applications

- Streets and highways

- Main and secondary roads

- Recreational parks and residential and industrial complexes

- Parking lots and shopping centers

The street lighting pole is the best option for lighting streets, highways, roads, access routes, and generally spaces that have low width and long coordinates and are produced in two models: tubular and polygonal.

Advantages of using street lighting

Currently, the reduction of energy consumption and the use of new energies are crucial because energy is one of the most valuable resources and is running out. Street lighting and parking lot lighting account for a substantial portion of a city’s overall electricity consumption. Therefore, reducing energy consumption in these lighting devices is very important.

Technical specifications of the street lighting pole

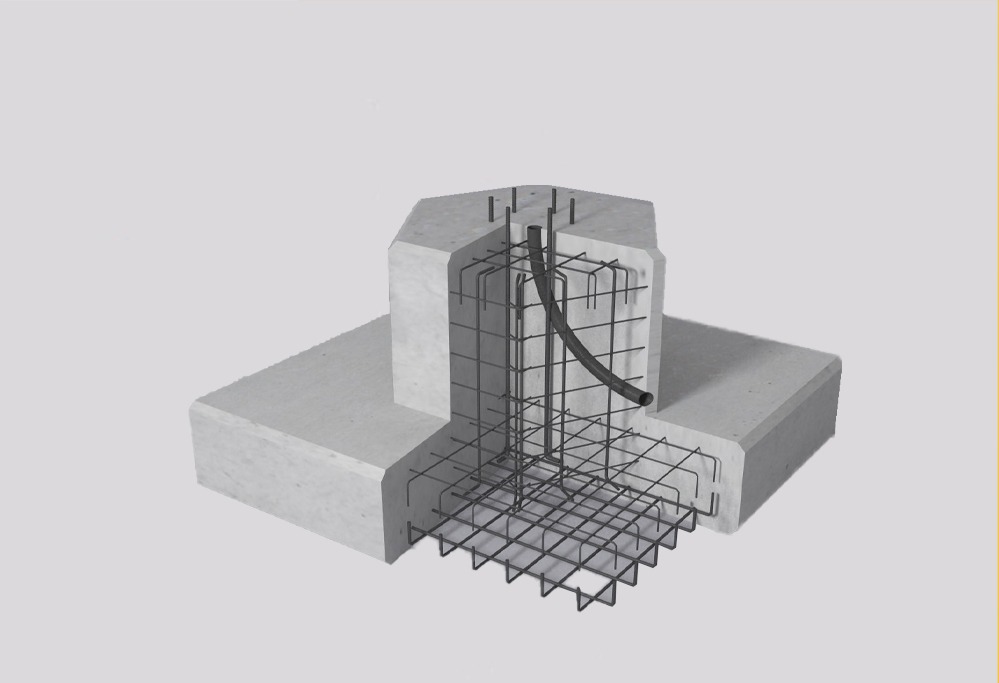

The main column of the pole is connected to the foundation by a square or circular iron plate called base plate and through several anchor bolts. Laches, similar to a triangle, are welded to the junction of the lighting pole and the base plate and enhance this connection. To manufacture a street lighting pole, its technical specifications must be determined, including the correct height of the structure, sheet thickness, top and bottom opening, light bulb type, coating and foundation, correct distance for installing the poles, and the number of brackets and their direction.

Street lighting pole price

The base price varies based on technical specifications. The following is effective on the base price: the type of bending, the quality of the bending, the weight of the light pole, painting type and quality, structure material if it is decorative, the size of the lower and upper sections and their number, the type and quality of galvanized coating, and the type of light bulb.

These poles are manufactured in different shapes and sizes with adequate number of headers, and the tube design and the distance between the poles are obtained by special software. The street lighting coating is determined according to the weather conditions and its durability. The street lighting pole coating can be hot-dip galvanized, electrostatic paint, epoxy paint, etc. You can contact Ehdas Gostar Nirooye Pars Engineering Company sales team to obtain the base price of street lighting pole or the price list of the lighting pole. Below is an example of colossal projects designed and implemented by the Ehdas Gostar team.